Welcome to Our Company

Natham NDT Training and Services

We are here since 2017 inthe fieldof NDT Services, Training and Manufacturing the Real Flawed Specimen, Calibration blocks, Validation blocks. We do NDT Services in order tomaintaintheintegrityofproducts like welding, castings etc.,inallkind of Industries Construction and Erection to ensure the quality of jobby providingwelltrained Non Destructive TestingTechnician’s. We do systemizeNDT training with a proper facility for both Theory and Practicalto qualify the candidates, who can be able to apply his NDT knowledgeto checktheintegrityof the product.

NNTS products are listed with the details. All of these Realflawed specimens which has been tested and performed by the specific NDT inspection done with the experienced operators top roduce the close to leran cemaster report with the length of the defect,datum of the defect and characterization of the defect.

WHY CHOOSE US?

NDT or NDE can be used to find size locate surface and subsurface flaws and defects.NDT plays a crucial role in everyday life is necessary to assure safety and reliability .NDT techniques can then be used to monitor the integrity of the items or structure throughout it’s design life sometimes.

NDT TRAINING

We do practical training for those who required the handson practice with the required Non Destructive testing method.We havewide NDT specimen collection to mold the candidate to be an eligible technician.We have a well established training center, with High quality standard for both theory and practical class

Conventional Ndt Courses

Penetrant Testing

PT is one of the most widely used NDT methods in industry.It is able to detect small discontinuities open to the surface regardless of their orientation or the shape of the part. PT isvery reliable,accurate,effective, surface inspection method process.

Radiography Testing

Radiography testing unofficially began in 1895 withelm roentgen,a German scientist,discovered that an unknown form of radiation emitted from a gas field electron tube was capable of penetrating objects that were opaque to the light.

Magnetic Particle Testng

A Magnetic field is used in the process of Magnetic Particle Testing. The material to be tested is magnetised by indirect or direct magnetization a magnetic field is formed when an electric current passes through the test material direct magnetization occurs during this phase. If any breaking of the magnetic things happen then iron particles are collect to form an indication.

Ultrasonic Testing

These early limitations were overcome in the 1940’s by the use of pulsed ultrasonic waves.Ultrasonic testing is a versatile volumetric examinations that is capable of usefully examining a wide range of thickness in many materials.

Advanced Course

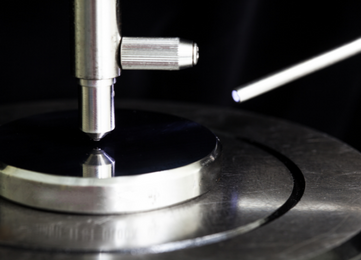

Eddy Current Testing

Eddy Current Inspectionis one of the several ndt methods that use the principal of electromagnetism as the basics of conducting examination. Eddy Current are created through a process called electromagnetic induction. Eddy Current Testing is now a widely used and well understood inspection technique.

Iris Tube Inspection

Internal Rotating Inspection System.IRIS is pulse echo based tube inspection technique. It uses ultrasonic wave. Ultrasonic can be used for the inspection of a various material including ferrous,non-ferrous and non-metallic tubing.IRIS can be used on ranged of diameters of 0.75 inch and thickness greater than 1 mm.

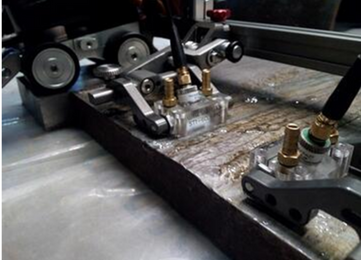

PAUT

Phased Array Ultrasonic Testing is also known as Phased Array UT, is an advanced non-destructive inspection technique that use a set of Ultrasonic Testing probe made up of numerous small elements. While the array refers to the multiple elements that make up a paut system.

TOFD

Time Of Flight Diffractionmethod of Ultrasonic Testing is a sensitive and accurate methods for the Non Destructive Testing of welds for defects.TOFD originated from tip diffraction techniques which were first published by silk and liddington in1975 which paved the way for tofd.

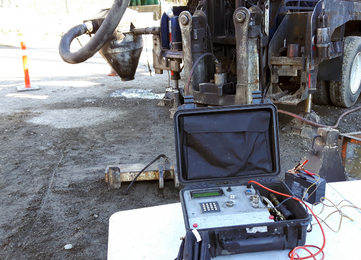

OUR SERVICES

Ultrasonic Testing

Magnetic Particle Testing

Penetrant Testing

Hardness Testing

Ferrite Testing

Post Weld Heat Treatment

Eddy Current Testing

Iris Tube Inspection

Rft Tube Inspection

Phassed Array Ultasonic Testing

Time Of Flight Diffraction